The ammonia nitrogen water quality online automatic monitor can monitor the change of ammonia nitrogen in water in real time, and upload the monitored data to relevant platforms through 485 and 232 communication modes. It can be applied to the monitoring needs of drinking water, surface water, groundwater, industrial wastewater, domestic sewage, aquaculture tail water and other industries. However, as a monitoring device, the most important thing is to detect the accuracy of the parameters. The accuracy of online monitoring instrument mainly comes from two aspects, one is the online automatic monitoring instrument itself. On the other hand, whether the calibration and maintenance of equipment by relevant personnel are in place in daily life.

By referring to the Technical Requirements and Detection Methods of Ammonia Nitrogen Water Quality Online Automatic Monitor, you can learn that the relevant technical requirements include the requirements for the composition of the instrument, the conditions of the use environment, the appearance requirements, the performance requirements, etc. Let's learn some knowledge together today.

Technical requirements for ammonia nitrogen water quality on-line automatic monitor

Composition requirements of ammonia nitrogen water quality monitor

The ammonia nitrogen water quality online automatic monitor is mainly composed of sampling, reagent storage, treatment, analysis and detection, control and other units.Sample injection/metering unit: including sample, standard solution, reagent and other introduction parts (including sample channel and standard solution channel) and metering part.

Reagent storage unit: a functional unit for storing various standard solutions and reagents to ensure the storage safety and quality of various standard solutions and reagents.

Physical/chemical pretreatment unit: remove the interference of water sample matrix by physical and chemical means or (and) complete the enrichment and dilution of the substance to be tested.

Analysis and detection unit: It is composed of reaction module and detection module. The control unit completes the automatic online analysis of the substance to be tested, and converts the measured value into the part of electrical signal output.

Control unit: it includes system control hardware and software, and it is used to realize sample injection, digestion, liquid discharge and other operations. It has the functions of data acquisition, processing, display and storage, security management, data and operation log query and output, as well as the functions of sample output and trigger sampling. The control unit can provide corresponding communication protocols when realizing the above functions, and the communication protocols meet the requirements of HJ212.

Environmental requirements for instrument use

Ambient temperature: 5 ℃~ 40 ℃;Relative humidity: 65% ± 20%;

Power supply voltage: AC voltage 220 V ± 22 V;

Power frequency: 50 Hz ± 0.5 Hz;

Water sample temperature: 0 ℃~50 ℃.

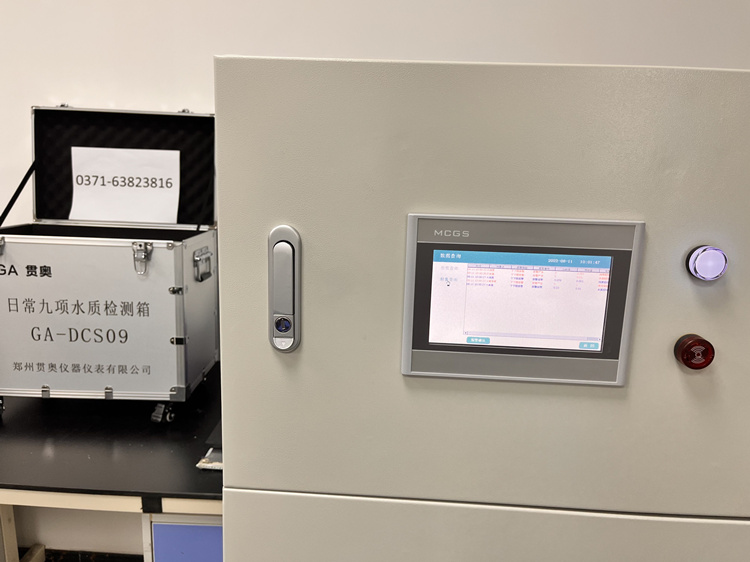

Instrument appearance requirements

The identification of the instrument shall comply with the requirements of GB/T 13306, and the nameplate shall be fixed at an appropriate and obvious position, which shall include the following contents:1. Power supply category;

2. Name and address of the manufacturer;

3. Instrument name, model and specification;

4. Factory number;

5. Date of manufacture;

6. Detection range and lower limit of quantification;

7. Operating environmental conditions.

8. The display shall be free of stains and damages. All display interfaces shall be in Chinese, and the characters shall be uniform and clear. The screen shall be free of dark corners, black spots, rainbows, bubbles, flickers and other phenomena, and the full program operation can be carried out according to the display prompts.

9. The case shell shall be made of corrosion-resistant materials, and the surface shall be free of cracks, deformation, dirt, burrs, etc. The surface coating shall be uniform, and free of corrosion, rust, peeling and wear.

10. The product assembly shall be firm, the parts shall not be loose, and the keys, switches, door locks and other parts shall be flexible and reliable.

11. The main parts of the product shall have corresponding identifications or text descriptions.

12. The product shall be marked with the analysis flow diagram at a conspicuous position of the instrument.

Performance requirements of instruments

1. Injection and metering unitIt shall be composed of anti-corrosion materials, and the determination results will not be affected by the corrosivity of reagents or samples. The metering unit shall ensure the stability and accuracy of reagent and sample injection. And it should be easy to clean and maintain.

2. Reagent storage unit

The materials used for reagents shall be stable and free from corrosion of stored reagents. The amount of reagent stored can ensure that the instrument can detect no less than 168 samples. During the detection period, keep the reagent consistent with the provisions in the instrument manual.

3. Physical/chemical pretreatment unit

During monitoring, when the interference of water sample matrix is serious and the sensor itself cannot overcome, corresponding processing unit shall be provided to eliminate the interference to the measurement results. In addition, it can have automatic heating device and temperature sensor, and can set heating time and temperature. Cooling device and safety protection device shall be provided to maintain constant temperature or pressure.

4. Analysis and detection unit

The analysis module of the instrument shall be made of anti-corrosion and high temperature resistant materials and easy to clean. The output signal of the detection module shall be stable. During operation, the signal converter has the function of converting the measured value into the corresponding electrical signal output (4 mA ~ 20 mA DC or RS232/RS485 interface). The test cycle of the whole instrument shall not exceed 60 min.

control unit

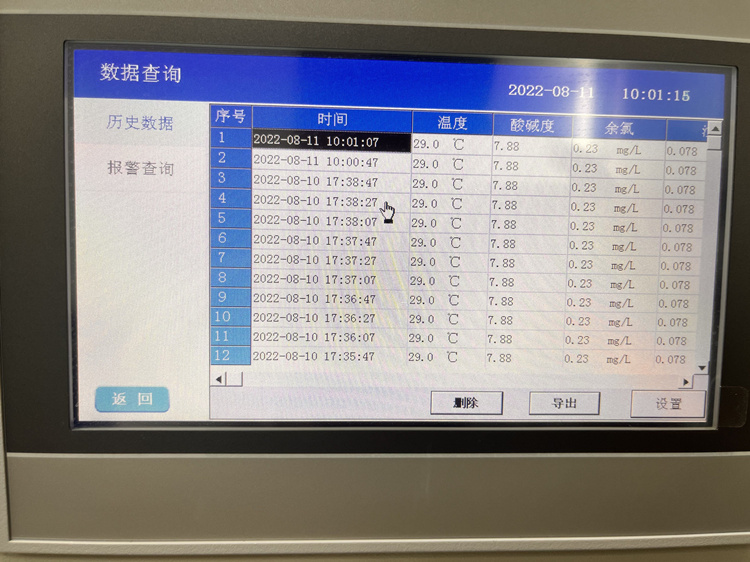

To ensure the accuracy of the instrument monitoring, the equipment must have a timing test function. In addition, it shall have manual and automatic cleaning functions for sample injection/metering, physical/chemical pretreatment units and analysis and detection units. It has manual and automatic calibration functions, can set automatic calibration cycle, and can automatically check standard samples.If the ammonia nitrogen online monitoring instrument contains multiple ranges, it shall have the function of automatic range switching, and be able to quickly display the final test results. All data, instrument parameters and operation logs shall be automatically collected, stored, processed, queried, displayed and output. The information shall be stored for at least 12 months of original data and operation logs. Different test data shall have the function of adding identification, and the specific identification shall comply with the relevant provisions of HJ 212.

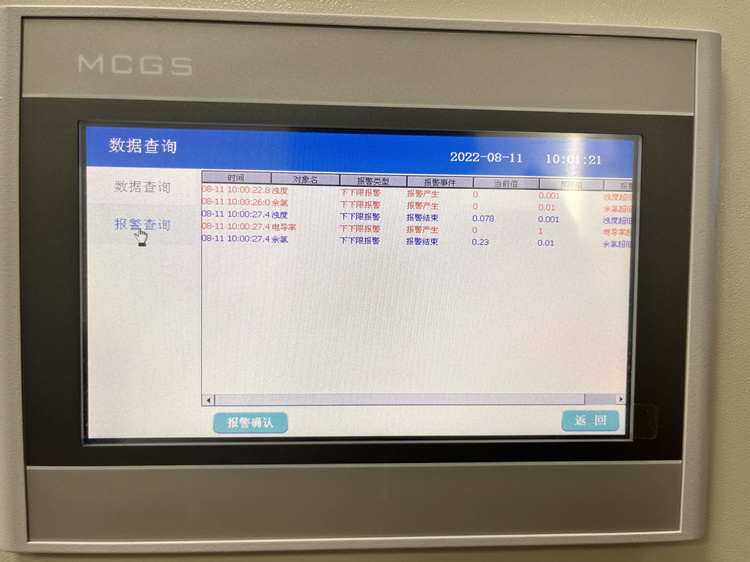

The measurement result of ammonia nitrogen online monitoring instrument is in mg/L, with 2 digits reserved after the decimal point. The monitored parameter values can output commands, relevant data and operation logs through the digital communication interface, and can receive remote control commands from the management platform, at least including remote startup and remote time synchronization functions. However, the data transmission shall provide the communication protocol and meet the requirements of HJ 212. The serial port output and network port output of monitoring data shall also be realized. Abnormal information shall be recorded, uploaded and fed back, which shall at least include: reagent shortage alarm, component fault alarm, liquid leakage alarm, sampling fault alarm and over standard alarm.

If the instrument encounters an unexpected power failure and is powered on again, it can automatically discharge the water sample and reagent being measured before the power failure, automatically clean each channel, and automatically reset to the restart test state. If it is in the heating and digestion state before power off, it can be automatically cooled after power on again, and automatically reset to the state of restarting the test. All system setting data, including calibration data, alarm data and operation data, will not change when the power is reconnected within 30 days of power failure.

The ammonia nitrogen online monitoring instrument should have three levels of operation and management authority, and the first level is the query authority, which can only query parameters, data and other information; The second level is the management authority, which can perform calibration, cleaning, parameter setting and other maintenance and repair operations on the instrument; The third level is the developer's permission, which can modify the kernel of the instrument.

In addition, the instrument must have the function of collecting and storing the analysis waste liquid and cleaning waste water, and should be treated according to the management requirements.