Our main purpose today is to enable everyone to understand the detection methods and significance of biochemical oxygen demand (BOD), and to master the operating skills of such methods.

Equipment required for biochemical oxygen demand detection

1. Constant temperature incubator2. 5-20l narrow mouth glass bottle

3.1000-2000ml measuring cylinder

2. Glass stirring rod: The length of the rod should be 200mm longer than the height of the measuring cylinder. At the bottom of the rod, a hard rubber plate with a diameter smaller than the bottom of the measuring cylinder and with several small holes is fixed.

5. Dissolved oxygen bottle: between 250-300ml, with a ground glass stopper and a bell-shaped mouth for water supply sealing.

6. The siphon tube is used for taking water samples and adding dilution water.

Reagents used in the detection of biochemical oxygen demand

1. Dissolve 8.5g potassium dihydrogen phosphate (KH2PO3), 21.75g dipotassium hydrogen phosphate (K2HPO4), 33.4g disodium hydrogen phosphate heptahydrate (N2HPO4.7H2O) and 1.7g ammonium chloride (NHC) in water and dilute The pH of this solution to 1000ml should be 7

2. Magnesium sulfate solution

Dissolve 225g of magnesium sulfate heptahydrate (MgSO·7H2O) in water and dilute to 1000ml.

3. Calcium chloride solution

Dissolve 27.5g of anhydrous calcium chloride in water and dilute to 1000ml.

4. Ferric chloride solution

Dissolve 0.25g of ferric chloride hexahydrate (FeCl3·6H2O) in water and dilute to 1000ml.

5. Hydrochloric acid solution (0.5mol/L)

Dissolve 40ml hydrochloric acid (=1.18g/m) in water and dilute to 1000ml.

6.>Sodium hydroxide solution (0.5mol/L)

Dissolve 20g of sodium hydroxide in water and dilute to 1000ml.

7. Sodium sulfite solution (1/2Na2SO2=0.025mol/L)

Dissolve 1.575g sodium sulfite in water and dilute to 1000ml. This solution is unstable and needs to be prepared every day.

8. Glucose-glutamic acid standard solution

After drying glucose (CH2O) and glutamic acid (HOOC--CH2CH2CHNH2-OOH) at 103°C for 1 hour, weigh 150mg of each and dissolve in water, transfer to a 1000ml volumetric flask and dilute to the mark, and mix well. Prepare before use.

9. Dilution water

Fill a 5-20L glass bottle with a certain amount of water, and control the water temperature at about 20°C. Then use an oil-free air compressor or a membrane pump to pass the inhaled air through the activated carbon adsorption tube and the water washing tube, and then introduce it into the dilution water for aeration for 2 to 8 hours, so that the dissolved oxygen in the dilution water is close to saturation. An appropriate amount of pure oxygen can also be introduced when aeration is stopped. The bottle cap is made of two layers of washed and dried gauze, placed in a 20°C incubator for several hours, so that the dissolved oxygen content in the water reaches about 8mg/L. Add 1ml of calcium chloride solution, ferric chloride solution, magnesium sulfate solution, and phosphate buffer solution to each liter of water before use, and mix them evenly.

The pH of the dilution water should be 7.2, and its BOD should be less than 0.2mng/L

10. Inoculum

You can choose any of the following methods to obtain a suitable inoculum.

①Urban sewage, generally domestic sewage, is placed at room temperature for a whole day and night, and the supernatant liquid is taken for use.

② Surface soil extract, take 100g garden or plant growth soil, add 1L water, mix and stand for 10min, take the supernatant for use

③Use river or lake water containing urban sewage

④The effluent of the sewage treatment plant

⑤When analyzing wastewater containing difficult-to-degrade substances, take a water sample 3~8km downstream of its sewage outlet as the domesticated inoculum of wastewater. If there is no such water source, you can take the neutralized or appropriately diluted wastewater for continuous aeration, add a small amount of this kind of wastewater every day, and at the same time add an appropriate amount of surface soil or domestic sewage, so that the microorganisms that can adapt to this kind of wastewater can multiply. When a large number of flocs appear in the water, or a sudden change in the decrease of the chemical oxygen demand is checked, it indicates that the applicable microorganisms have reproduced and can be used as an inoculum. The general domestication process takes 3-8d.

11. Inoculation of dilution water

Divide an appropriate amount of inoculum, add it to the dilution water, and mix well. The amount of inoculum added per liter of diluted water is: 1~10ml of domestic sewage; or 20~30ml of surface soil extract; or 10~100ml of river water and lake water.

The pH value of the inoculation dilution water should be 7.2, and the BOD value should be between 0.3 and 1.0 mg/L. Use the inoculation dilution water immediately after preparation..

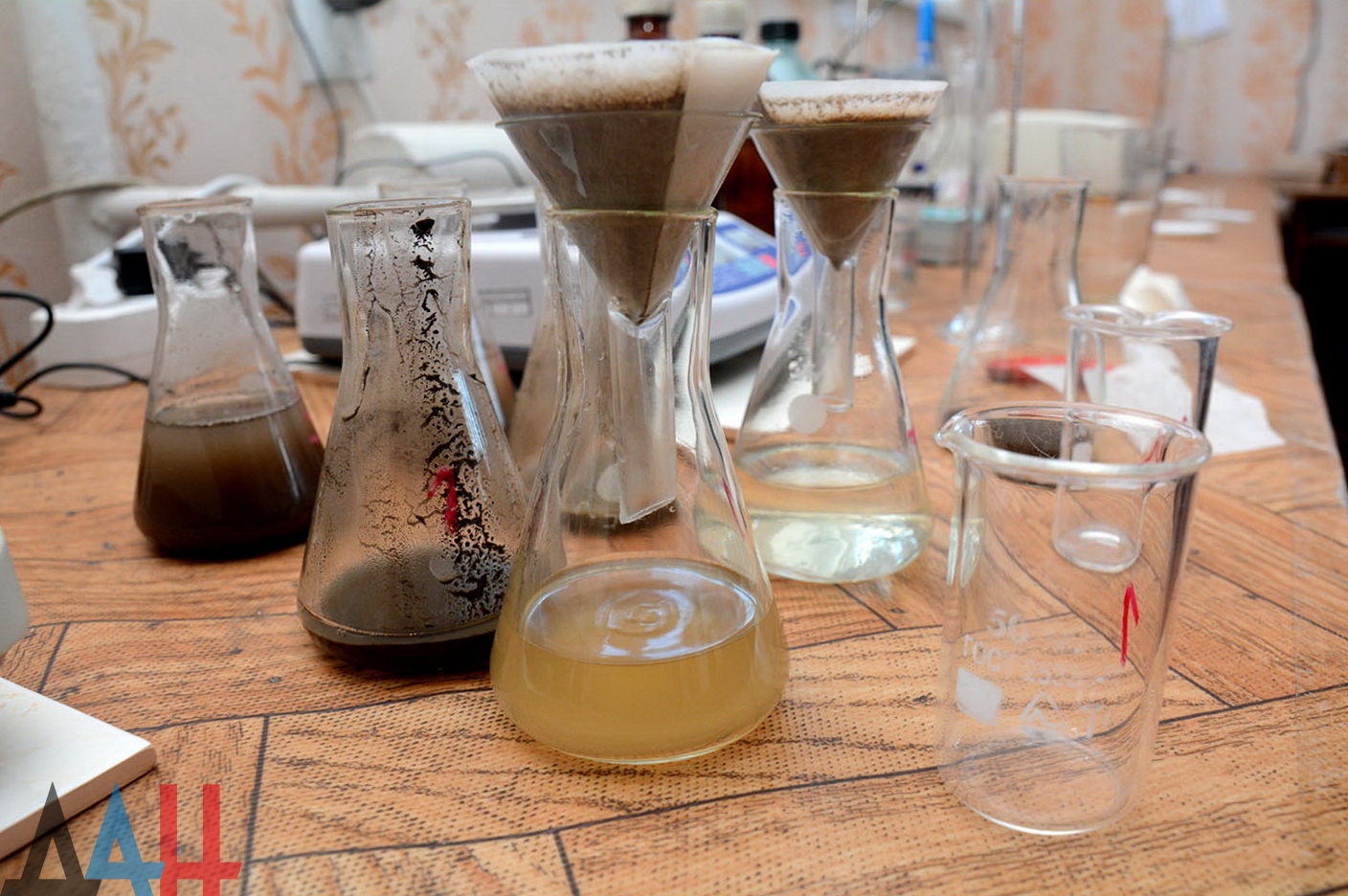

Detection of biochemical oxygen demand in water

1. Determination of undiluted water samples(1) Ground water with high dissolved oxygen content and low organic content can be directly siphoned without being diluted, and the mixed water sample at about 20°C is transferred into two dissolved oxygen bottles. Pay attention to the transfer process Do not make bubbles. Use the same operation to fill the two dissolved oxygen bottles with water samples and then overflow a little and stop them. There should be no air bubbles in the bottle.

(2) One of the bottles was immediately measured for dissolved oxygen, and the mouth of the other bottle was sealed with water, then placed in an incubator and incubated at 20+1°C for 5 days. Pay attention to adding sealing water during the cultivation process. Counting from the beginning of putting it in the incubator, after five days and nights, the sealing water was discarded and the remaining dissolved oxygen was measured.

2. Determination of diluted water sample

(1) Determination of dilution factor: According to practical experience, the following calculation method is proposed for reference during dilution.

①Surface water: calculate the dilution factor by multiplying the measured permanganate index and a certain coefficient.

②Industrial wastewater: Determined by the COD value measured by the potassium dichromate method. Usually three dilution ratios are required. When using diluted water, the COD value is multiplied by the coefficients 0.075, 0.15, 0.225 respectively to obtain three dilution multiples. When using inoculation dilution water, multiply by three coefficients of 0.075, 0.15 and 0.25 respectively.

Note: The CODer value can be estimated by using the standard color column prepared by the calibration test of the potassium hydrogen phthalate solution according to the same procedure as the COD measurement when heating to reflux for 60 minutes during the COD determination.

Finally, through calculation, the biochemical oxygen demand of the direct culture water sample without dilution, and the biochemical oxygen demand of the culture water sample after the dilution have been obtained.