Details to pay attention to when handling phosphate water samples

1. When detecting phosphate in water, nitrite will interfere with the results. You can use sulfamic acid to eliminate it in advance. Generally, 100mg sulfamic acid can process 32.9mg/L of nitrite.2. If arsenate exists in the water, it will cause positive interference. You can use sodium thiosulfate to reduce it to arsenite to eliminate the interference.

3. When the fluoride in the water sample is greater than 200mg/L, the color development will be inhibited.

4. When the content of iron ions in the water sample is less than 10mg/L, the influence will not exceed 5%; vanadate will cause the color to deepen, and Cr3+ will not interfere within 10mg/L, only when it reaches 50mg/L, it will cause water The sample absorbance increased by 5%.

5. Silicate within 5mg/L will not affect the test results, but high concentration of silicate will cause an increase in absorbance.

6. When the phosphate content is high, less water samples can be taken. For example, when the content is 0-5mg/L, the sampling volume should be 12-40mL; when the content is 5-10mg/L, the sampling volume should be 6-12mL; and when the content is 10-20mg/L, the sampling volume should be 3-6mL; If it is greater than 20mg/L, it needs to be sampled after dilution.

7. If the alkalinity of the water sample is too high, it can be neutralized with sulfuric acid.

8. Phosphate water samples should be tested immediately after taking the amount. If it is not possible to test immediately, sodium chloride and mercury chloride can be added in sequence for protection. When the sodium chloride content in the water sample reaches 50mg/L and the mercury chloride 40mg/L, it is stored in a glass bottle in a refrigerator at 0-4°C.

9. Phosphate water samples should be filtered as quickly as possible, generally not more than 10 minutes, otherwise it is easy to have adsorption effects and interfere with the test results.

Problems that need to be paid attention to when detecting operation

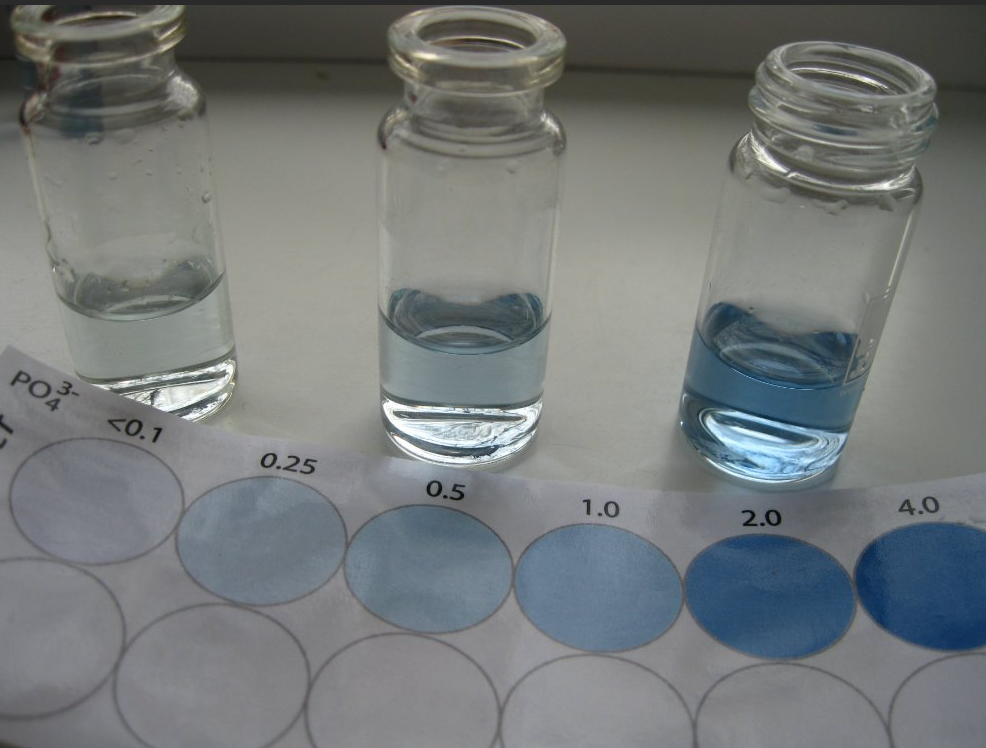

1. The color development of molybdenum blue method is related to the acidity of the final solution, the concentration of molybdate, the type and amount of reducing agent, the temperature and time of color development, so it is necessary to keep the same.2. The temperature should be controlled at about 30°C during color development.

3. The resting time should be as consistent as possible.

4. All glassware used should be soaked in dilute hydrochloric acid or dilute nitric acid to eliminate adsorption. Do not touch phosphoric acid and salts to avoid pollution. The glassware used in the color development process should be cleaned frequently with sodium hydroxide solution (2mol/L) to remove colored precipitates and avoid affecting the measurement results.

5. When preparing the ammonium molybdate solution, it should be noted that the ammonium molybdate is formulated into an aqueous solution, and then slowly added to the sulfuric acid solution. If the operation is reversed, it will cause insufficient color rendering.

6. Because the color of molybdenum blue will darken first and then become lighter with the prolonged storage time, after adding the ascorbic acid solution, the color should be compared immediately after 10 minutes, and the total time should not exceed 15 minutes.

7. Since acidity affects the slope of the working curve, ammonium molybdate solution should be added accurately when testing.